I-belt conveyor iwuhlobo lwe-friction drive ukuthutha izinto ngendlela eqhubekayo.Inezinzuzo zomthamo oqinile wokudlulisa, ibanga elide, isakhiwo esilula nokugcinwa kalula.Isetshenziswa kabanzi ezimayini zamalahle, i-electronics, imishini, izinto zokwakha, amakhemikhali, imithi, njll.

Ukuhluleka kweyunithi yokudlulisela okubangelwa enye nenye

Ukuhluleka kwebhande lokuthutha

Ukuhluleka kwesigubhu

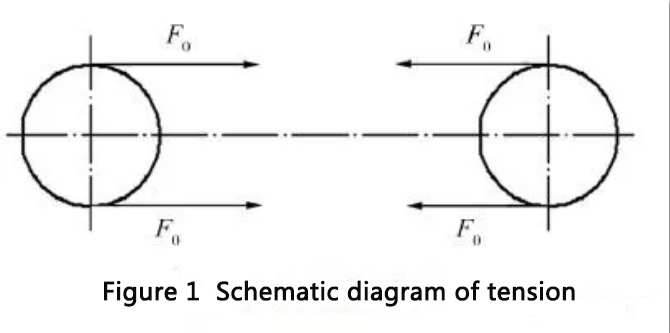

Kunezinhlobo ezine eziyinhloko zokwehluleka kwesigubhu.1 Ekukhiqizeni, ukungezwani kwebhande lokudlulisa u-F0 kuzokwehla kancane kancane (bheka uMdwebo 1), ukuze ukungqubuzana phakathi kwebhande lokuhambisa kanye nesigubhu kunciphe, okubangela ukuthi isigubhu kanye nebhande lokuthutha kushelele;Ibhande eli-2 lokuthutha liletha amanzi, udaka lwamalahle noma uwoyela ongcolile kanye nezinye izinsalela esigubhuni nasebhandeni lokuthutha, okubangela ukuba i-roller nebhande lokuthutha lishelele;3 Ubuso berabha eginqikayo buyisicaba noma buguge, okuholela ekwehleni kwesici sokungqubuzana, okuholela ekwehleni kokungqubuzana phakathi kwebhande lokuhambisa kanye nesigubhu, okubangela ukuthi i-roller kanye nebhande lokuhambisa kushelele;Ngaphansi kwesenzo sokushuba kwebhande le-conveyor, i-roller shaft bearing iyaguga futhi ihlehle, ibangele ukuthi indawo yayo ishintshe, ibangele ukuba ibhande lokuthutha libaleke noma i-roller nebhande lokuhambisa lishelele, okuholela ekuhlulekeni komsebenzi.

Ukuhluleka kwerola

Kunezinhlobo ezintathu eziyinhloko zokuhluleka kwama-roller.1 Phakathi nenqubo yokusebenza, ukungqubuzana phakathi kwe-idler nebhande lokudlulisa kuyakhiqizwa.Isiqondiso sokugijima sebhande lokuthutha kanye nesiqondiso sokujikeleza kwe-roller kune-angle yokuthambekela ethile.Lapho i-roller ijikeleza, ingaphansi komthwalo we-eccentric, okuholela ku-roller surface kanye ne-roller bear.Ukugqoka nokudilika, njengoba isikhathi sihamba, kubangela ukuba i-roller ihlukane phakathi, ukujikeleza kwe-roller okuthwele akuguquki noma akuguquki, futhi ngisho nokuthwala kukhishwa, ubuso be-roller kanye nesihlalo sokuthwala kuyahlukaniswa, futhi i-welding iyasuswa, ngaleyo ndlela ibangele ukuthi ibhande lokuthutha lisebenze.Ukuchezuka, ukwanda kokumelana nomsebenzi kanye nokwehluleka kwezinto ezibonakalayo;2 Ibhande le-conveyor liletha amanzi, udaka lwamalahle noma uwoyela ongcolile endaweni yokuthinta i-roller kanye nebhande lokuhambisa, ukuze umkhiqizo ungene ngaphakathi kwe-roller bear, ungcolise amafutha okugcoba, ucekele phansi ukuthambisa okuvamile kwe-bearing, futhi kubangela ukuthwala umonakalo;3 ukudlulisa Izinto ezisebhandeni zichema ohlangothini olulodwa ukuze zenze umthwalo we-eccentric, futhi umthwalo ohlangothini lwe-idler we-roller uyakhuphuka, okusheshisa ukuguga kwe-roller surface kanye ne-roller bear, okwenza umonakalo ku-roller kanye. kubangela ukwehluleka komsebenzi.

Ibhande lokuthutha liyehluleka ngenxa yokushintsha kobubanzi besigubhu

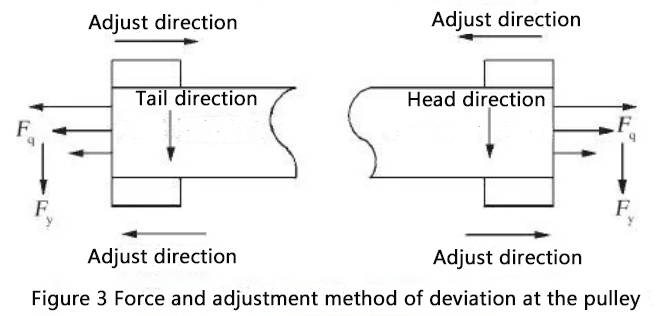

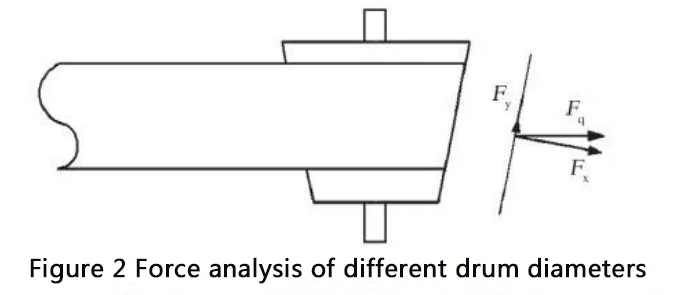

Ngenxa yephutha lomshini wesigubhu ngokwawo, indawo engaphezulu ibambeke ngezinto ezibonakalayo noma ukugqoka okungalingani kubangela ukuthi ububanzi bushintshe.Amandla okudonsa u-Fq webhande lokuthutha akhiqiza amandla ashukumisayo e-Fy ohlangothini olukhulu lobubanzi besigubhu.Ngaphansi kwesenzo samandla wengxenye enyakazayo ye-Fy, ibhande lokudlulisa likhiqiza irola liye kurola.Uma ububanzi bukhulu, ibhande lokuthutha lizokhuphukela engxenyeni engenhla, njengoba kuboniswe kuMfanekiso 3, okwenza umsebenzi wehluleke.

Ukwehluleka okubangelwa ukugotshwa kwebhande lokudlulisa esigubhu

Lapho ibhande lokuthutha lifakwa esigubhuni, liyogoba.Uma inani lokugoba lifinyelela umkhawulo wokukhathala, ukwehluleka ukugoba kuzokwenzeka.Ekuqaleni, kuzovela imifantu emincane.Ngokuhamba kwesikhathi, ukuqhekeka kuzokhula noma kudabuke, okuzogcina kwenze ibhande lokuthutha ligqabuke futhi kubangele ukwehluleka komsebenzi.

Ukuhluleka kwerola

Ibhande lokuthutha alisebenzi kahle noma ibhande lokuthutha lonakele ngenxa yokunamathela phezulu.

Ngenxa yephutha lokufaka, iqembu lerola elithwele umthwalo linoshintsho lwesikhundla ngesikhathi senqubo yokukhiqiza noma indawo engaphezulu yerola ibambeke ngediphozithi efana ne-slime, okungabangela ibhande lokudlulisa ukuthi ligijime liye ohlangothini olulodwa eqenjini ama-roller, okuholela ekuhlulekeni komsebenzi.

Ukuhluleka kwebhande lokuthutha okubangelwa ukulimala kwerola

Ngemva kokuba i-roller igugile, ingaphezulu lensimbi liyaqhekeka noma i-roller iphakanyiswe ngaphansi komthwalo onomthelela, okubangela ukuguga okungavamile noma ukuklwebheka kwebhande lokuthutha, noma lidatshulwe, ekugcineni kubangele ukuphuka kwebhande lokudlulisa futhi kubangele ukwehluleka komsebenzi.Izinyathelo zokuthuthukisa, ukuhlolwa nokugcinwa ngesikhathi

Uma ibhande lokudlulisa lixega esigubhuni futhi lishelela, ukushuba kulungiswa ngendlela yokuqinisa isisindo, ukucindezelwa ngezikulufu, ukuqina kwe-hydraulic, njll., ukuze kuqedwe iphutha lokushelela.Kodwa-ke, lapho ibhande lokudlulisela likhubazekile unomphela, ukushuba kwe-stroke akwanele, futhi ibhande lokudlulisa linganqanyulwa isikhathi sokujoyina kabusha.

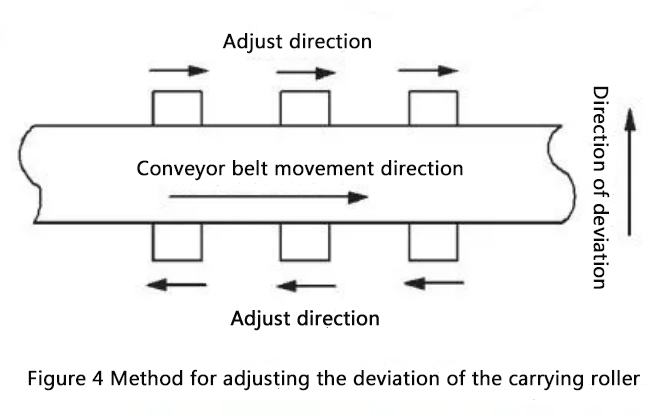

Uma kunamanzi, udaka lwamalahle noma amafutha angcolile ebusweni bebhande lokuthutha, i-roller ne-roller, kufanele ihlanzwe ngesikhathi ukuze kugcinwe indawo yokudlulisa izingxenye zomile.Uma imvelo imanzi, i-rosin ingafakwa esigubhini ukuvimbela ukushelela.Uma ingaphezulu lebhande lokuhambisa liqhekekile, indawo yenjoloba yesigubhu yonakalisiwe, futhi i-roller ayisebenzi noma yonakaliswa, kufanele ilungiswe noma ishintshwe ngesikhathi.I-lubricant ephethe kufanele ihlanzwe futhi igcwaliswe njalo, futhi umsebenzi awukwazi ukuqhubeka ukuvimbela amaphutha amaningi noma izingozi zokuphepha.Uma ukuchezuka kwenzeka, njengoba kuboniswe kuMfanekiso 2, isiqondiso se-roller ye-head drive njengoba kuboniswe umcibisholo.Ingxenye engenhla yesigubhu iya kwesokunxele noma ingxenye engezansi iya kwesokudla.Ukugcina ukungezwani kwebhande, isigubhu sisesimweni esifanele.Indawo, isigubhu sokuqondisa kabusha umsila silungiswa sibheke ngakolunye uhlangothi lwerola ye-head drive.Uma isikhundla somuntu ongenzi lutho singalungile, indlela yokulungisa injengoba kukhonjisiwe ku-Fig. 4. Iluphi uhlangothi lwebhande lokudlulisa oluchemile, yiluphi uhlangothi lwesethi ye-roller oluya ohlangothini olufanele lwebhande lokudlulisa, noma olunye uhlangothi ethuthiwe.Ngokuphambene nokulungiswa kokunyakaza, kuyadingeka ukulungisa ama-roller amaningana aseduze lapho kuchezuka ukuze kuqedwe.

Izingxenye zokudlulisela zifanelekile futhi inqubo ihlangabezana nezidingo.

Izinga lezingxenye zokudlulisa ezifana nebhande lokuthutha, i-roller kanye ne-idler kufanele ifaneleke, futhi ukwehluleka komsebenzi ngenxa yephutha lokukhiqiza isigubhu ngokwaso akufanele kwenzeke.Inqubo yokufaka nokugcinwa kwezingxenye zokuthutha ibhande ihlangabezana nezidingo, futhi iphutha alikwazi ukweqa izinga.I-conveyor kufanele ihambe kahle ukuvimbela ukugcwala ngokweqile noma ukushaqeka kwemithwalo.

Ekukhiqizeni kwangempela, kuyadingeka ukuqinisa umthwalo wemfanelo womshayeli webhande elihambisa ibhande kanye nabasebenzi bokuhlola, ukusebenzisa ngokuqinile ukusebenza kwe-conveyor yebhande, izinhlelo zokuhlola nokugcinwa, ukuhlaziya ngokucophelela nokwahlulela amaphutha atholiwe, nokugcina ngesikhathi.Gwema ukwenzeka kwezingozi ezinkulu, wandise impilo yesevisi yezingxenye zokudlulisela njengamabhande okuthutha, ama-roller nama-roller, futhi uthuthukise ukusebenza kahle kokukhiqiza.

Isikhathi sokuthumela: Jan-20-2023