I-Coal Mining Industry Trough Self Aligning Roller

Ulwazi Oluyisisekelo

| Indawo Yomsuka: | Qingdao China |

| I gama le-brand: | I-TSKY |

| Isitifiketi: | ISO, CE, BV, FDA |

| Inombolo Yemodeli: | TD 75,DTⅡ |

| Inani elincane le-oda: | 10 amasethi |

| Inani: | Kuyaxoxiswa |

| Imininingwane yokupakisha: | i-pallet, isitsha |

| Isikhathi sokuthumela: | 5-8 izinsuku zokusebenza |

| Imigomo Yokukhokha: | L/C, D/A, D/P, T/T, Western Union |

| Ikhono Lokuhlinzeka: | 5000 amasethi/ngenyanga |

Imininingwane Yemininingwane

| Okubalulekile: | Irabha, Insimbi | Okujwayelekile: | I-DIN, JIS, ISO, CEMA, GB |

| Usayizi: | Usayizi Owenziwe Ngezifiso, Phezu Umdwebo | Isimo: | Okusha |

| Isicelo: | Usimende, Imayini, Imayini Yamalahle, Inkwali, Imboni | I-Bearing: | NSK, SKF, HRB, Ball Bearing, NTN |

| Ukukhanya Okuphezulu: | I-CEMA self aligning roller, Ukuzilinganisa ngokuzilinganisa ungenzi lutho, I-JIS self aligning roller yokuthutha ibhande | ||

Incazelo Yomkhiqizo

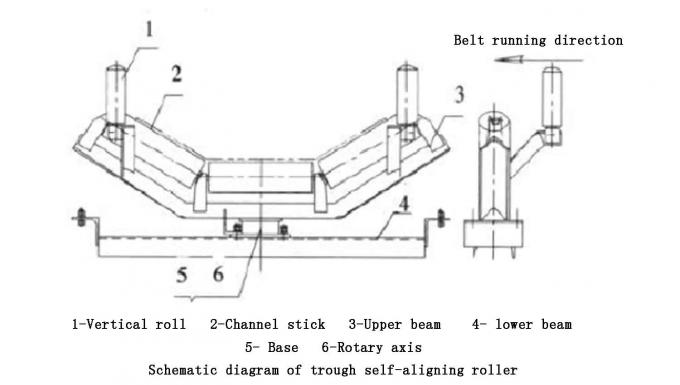

I-roller yokuziqondanisa emgqonyeni

Amavila aholayo aqondisa ngempumelelo ukuthuthwa kwezinto ezihlukahlukene ku-conveyor.Lawa marola angasebenzi ngokuvamile agijima ngaphansi kwebhande lokuthutha futhi akhe i-trough esiza ukugcina izinto ezixegayo zingawi ngephutha ibhande lokuthutha.

Isingeniso se-roller:

I-roller iyingxenye ebalulekile ye-conveyor yebhande.Kunezinhlobo eziningi kanye nenani elikhulu, elingasekela isisindo sebhande lokuhambisa kanye nezinto ezibonakalayo.Ibalelwa ku-35% yenani eliphelele le-conveyor yebhande futhi ikhiqiza ukumelana okungaphezu kuka-70%, ngakho ikhwalithi ye-roller ibaluleke kakhulu.

Umgomo wokusebenza werola eliziqondanisa lomgodi:

Uma ibhande lokudlulisa lichezuka, liqhubezela iqembu lerola eliziqondanisa le-trough ukuthi liphambuke, ukuze i-roller ikhiqize amandla okungqubuzana athuthukisa ibhande lokudlulisa ukuze libuyisele indawo yalo yokulingana, ukuze kufezwe injongo yokulungisa ibhande lokuthutha.

Indima yerola eliziqondanisa le-trough:

Isetshenziselwa ukusekela uhlangothi lomthwalo webhande le-conveyor ukulungisa ukuchezuka kwebhande lokuthutha ukuvimbela izinyoka nokuqinisekisa ukusebenza okuzinzile kwebhande lokudlulisa.

Izici zerola eliziqondanisa le-trough:

Uma inani lokuchezuka lilincane, i-engeli yokuzungeza ye-roller ohlangothini lokuchezuka incane, futhi i-thrust yangemuva ekhiqizwa ibhande lokuhambisa nayo incane;

Uma inani lokuchezuka likhulu, i-engeli yokuzungezisa yerola engenzi lutho ohlangothini lokuchezuka inkulu, futhi ukusunduza okuseceleni okukhiqizwa ebhandeni lokudlulisa nakho kuba kukhudlwana.Ngale ndlela, ukulungiswa okuzenzakalelayo kwamanani ahlukene okuchezuka kuyabonakala.

Omunye umsebenzi we-deflection stop roller nawo ungavimbela ngokuqondile futhi unciphise ukuphambuka kwebhande lokuthutha uma kwenzeka ukuchezuka okukhulu.Ngaphansi kwesenzo esihlanganisiwe se-roller yokuziqondanisa umkhombe, ibhande lokudlulisa lingagxiliswa kancane kancane.Ibhande liphuma endaweni yokubeka.

Ukusebenza kwerola eliziqondanisa le-trough:

1. Ngaphambi kokusebenzisa i-roller, hlola ngokucophelela ukubukeka kwanoma yimaphi amaqhubu amakhulu kanye nomonakalo.Irola ezungezayo kufanele ijikeleze ngokuguquguqukayo ngaphandle kokugxumela.

2. Ibanga lokufakwa kwamarola kufanele linqunywe izibalo zesayensi ezisuselwe ohlotsheni lwempahla kanye nezici zomthumeli, futhi ugweme ukufakwa ngokweqile noma okuminyene.

3. Ukufakwa kwe-roller kufanele kushintshwe ukuze kugwenywe ukungqubuzana phakathi komunye nomunye.

Ukunakekelwa kwerola eliziqondanisa le-trough:

1. Impilo evamile yesevisi ye-roller ingaphezu kuka-20000h, futhi ngokuvamile ayidingi ukulungiswa.Kodwa-ke, ngokwendawo yokusetshenziswa kanye nobukhulu bomthwalo, kufanele kusungulwe usuku oluhambisanayo lokunakekela, ukuhlanzwa okufika ngesikhathi kanye nokugcinwa komjovo kawoyela, kanye nokuhlanzwa ngesikhathi kwamalahle antantayo.Amarola anomsindo ongajwayelekile futhi angaphenduki kufanele ashintshwe ngesikhathi.

2. Uma ushintsha i-bearing, ukuvuleka kwe-cage yokuthwala kufanele kuvulwe ngaphandle.Ngemuva kokuthi i-bearing ifakwe ku-idler, imvume efanele kufanele igcinwe futhi ingachotshozwa.

3. Izimpawu ze-labyrinth kufanele zenziwe ngezingxenye zangempela, futhi kufanele zifakwe kuma-rollers ngesikhathi somhlangano, futhi akufanele zihlanganiswe ndawonye.

4. Ngesikhathi sokusetshenziswa, i-roller kufanele ivinjwe ngokuqinile ekushayeni i-roller tube ngezinto ezinzima.

5. Ukuqinisekisa ukusebenza kokuvala nokusebenzisa ukusebenza kwe-roller, akuvunyelwe ukuhlakaza i-roller ngokuthanda kwayo.